|

|

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Messages - jmunkki

Pages: [1]

1

« on: August 28, 2022, 05:56:48 AM »

2

« on: August 05, 2022, 01:38:02 AM »

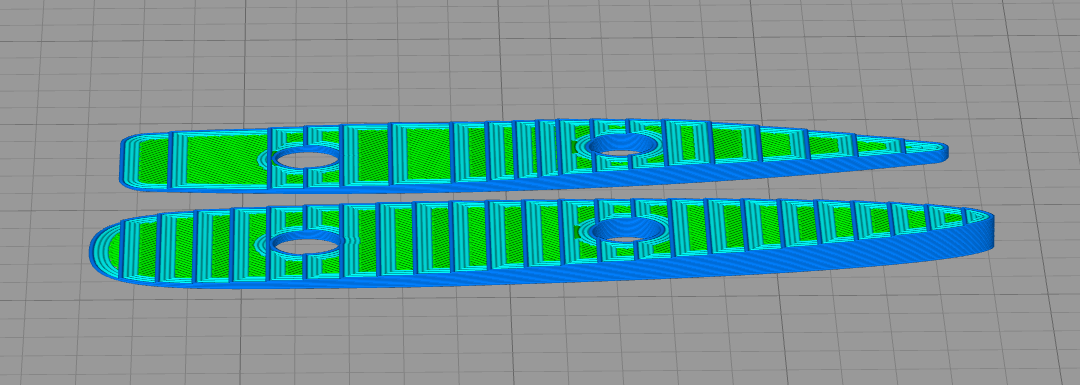

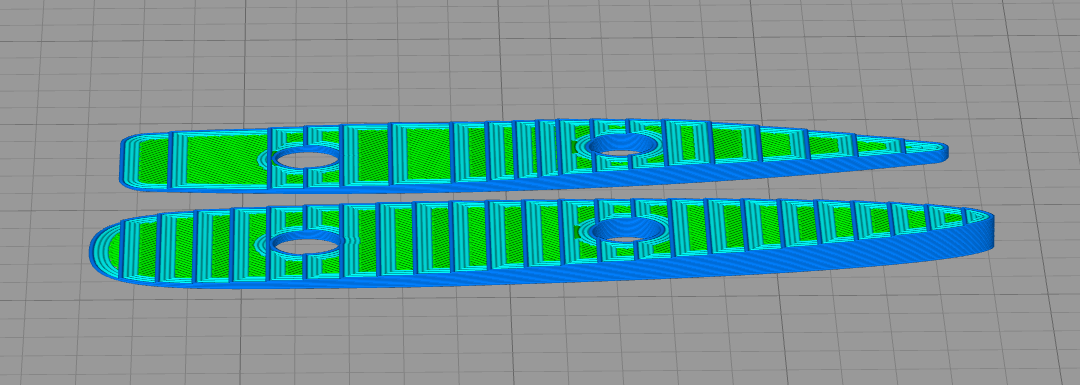

I tried the KD Maui shims with my Takuma Helium. They are a bit shorter than the ones by Gyre, but symmetrical, so easily reversed. I think either of these will work fine with the standard fuselages from Takuma. However, I decided to make my own designs because I'm using a custom fuselage from Jim Stringfellow. I noticed the curve on it in the stabilizer area isn't quite as pronounced as in the original Takuma or on the stabilizers. This produced a rocking chair effect where the area between the two screw pushed against the stabilizer. So instead of having a straight line profile in the shim, I'm setting the angle using the area around the screws and then have a slight concave between the screws. The ends also taper down on both sides. This essentially very much like using two washers of different thicknesses to adjust the stabilizer angle. It eliminates the rocking chair problem, so I also made a zero shim where the areas around the screws are equal, but everything else is slightly thinner. My shims are also slightly narrower to match the shape of Jim's fuselage better (but they'll still fit standard Takuma fuselages too). I'll do a bit more testing and probably post these for free at some point in the future. I managed to a little bit of testing yesterday, but my timing and the wind didn't line up all that great, so I didn't get a whole lot of foiling time yet, unfortunately. I took a screenshot of the -2.0 shims (mine + Gyre's) sliced for FDM printing side by side. You can see that these are identical around the screws, but where the layers on Gyre's shim are evenly spaced (meaning it's a flat slanted surface), mine are uneven (meaning the top surface is slightly curved). My version is also slightly shorter (but much longer than the KD Maui shims). The shim size text is on the bottom of my shim, so you can't see it in the screenshot. KD Maui has the shim sizes cut through the whole shim and Gyre's don't seem to have sized etched on them.

3

« on: August 01, 2022, 02:20:09 AM »

KD Maui offers free STL files for stabilizer shims here: https://kdfoils.myshopify.com/collections/extras/products/shim-packI downloaded the Takuma set, but I haven't used it yet. I do a lot of 3D-printing. I burned out doing software and needed to do something else for at least a while, so I quit my job in December and started a company. I was initially doing a mix of software consulting (to pay the bills), 3D printing-related projects and of course all the paperwork to get the company going. I wanted to do a Patreon, but there are legal issues related to Patreon if your Finnish (like me), so I decided to just try to sell the models for a reasonable price on MyMinifactory and make Youtube videos to introduce the projects. So, my Winging-related prints are not free, but I hope they aren't too expensive. This summer has been 50% trying to improve my winging (lots of time on the water) and 50% working on the 3D-printing projects and videos. My first three "products" are all Duotone-related. There's a pump/valve adapter (since Duotone uses their own valve and doesn't include an adapter for generic pumps with their wings) and there are some 3D-printable front/back ends for wing booms. I like the hockey stick boom project because you're essentially recycling one man's garbage into a $200 carbon boom and spending less than $10 on the materials (and $10 for the 3D file unless you feel like making your own). They haven't sold much at all, so definitely not a viable business, but I guess there aren't that many Duotone wingers with 3D printers who are also aware of my work quite yet. The next project in my release queue is pretty close to ready. It's a screwdriver handle that is specifically designed for hydrofoil assembly/disassembly, so it's not brand specific and should be useful to all types of foiling (and probably even some applications outside of foiling). I made the first prototypes about a year ago and I have had a couple of friends testing them. You need some screws and of course tool bits from the hardware store in addition to the 3D printed part. It could definitely be also made (better) with more traditional manufacturing, but the 3D printed versions work great too. I wouldn't mind working with foil companies to allow them to ship their foils with my "GyroKey". The L-shaped Torx driver that I got with my Takuma Helium had very loose-fitting Torx heads and it even got a little bit rusty only after a few weeks of use, so I just decided to make something better myself. It would be nice if foils came with really good assembly tools. I still have the "legendary" F2 footstrap screwdriver and it still works after decades of use installing footstraps. Starboard had a "Tiki Tool" for footstraps, but I think they discontinued that pretty quickly (mine just broke all too easily for some reason).

5

« on: July 13, 2022, 03:35:04 AM »

My first version of a round tube boom head was also a bit on the heavy side, but it worked.

This morning, I modified the CAD files for the ice hockey stick head to use a round profile and made 25mm and 27mm versions that look OK. My 29mm version still needs a slight tweak before I would trust it to be strong enough.

I'm going to print a 25mm version, install it on the 25mm alu tube and check that it fits and works and then publish the files. Testing will be much more limited than for the hockey stick version, but the model is very similar. Printed weight is under 40g, which I think is light enough.

6

« on: July 12, 2022, 04:12:32 AM »

Sorry for the thread necro, but I think with the Slick SLS, there's probably renewed interest in custom booms. Also, I just released a video and some 3D models to convert broken ice hockey sticks into Slick carbon booms, so that may be of interest as well. Here's the Youtube video I made: And this is where the 3D model files are for 3D printing: https://www.myminifactory.com/object/3d-print-hockeyboom-wingfoil-boom-duotone-slick-compatible-233110Even if you don't have a 3D printer of your own, a local library or makerspace is likely to allow you to print the pieces you need as they are small enough to print in just a couple of hours. As far as diameters for round tubes go, I made an alu boom before I started using the hockey sticks and 25mm diameter was great. Once you add a grip, it's very similar to the Duotone booms (although they have a slightly oval cross section). 27mm is probably fine, but anything over that is going to feel pretty big unless you have very large hands. I'm probably going to release some 3D-printable files for round profiles in the near future. While broken or used hockey sticks are easily found in many parts of the world, they can be a bit harder to obtain in others. I think hockey sticks are great because broken sticks are often still long enough to be used for booms, they are very stiff, strong and lightweight and the most recent ones have a sticky coating, so you can opt out of adding a rubber grip entirely (especially for winter winging with gloves on). If there's a hockey rink nearby, you may be able to get the stick free from a garbage bin (ask a janitor or coach for permission).

Pages: [1]

Recent Posts

Recent Posts

|

Re: Sunova Ghost 8'10 SUP

[Classifieds]

|

kliss99

Today at 05:01:39 AM

|

|

Re: Need a new Impact Vest

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

PonoBill

April 23, 2024, 07:55:28 PM

|

|

Re: Need a new Impact Vest

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

B-Walnut

April 23, 2024, 07:26:43 PM

|

|

Re: Need a new Impact Vest

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

spindrift

April 23, 2024, 07:16:46 PM

|

|

Re: Need a new Impact Vest

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

B-Walnut

April 23, 2024, 06:56:28 PM

|

|

Need a new Impact Vest

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

spindrift

April 23, 2024, 06:36:51 PM

|

|

Re: Ocean Rodeo Glide-Allula

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

kiteboarder

April 23, 2024, 06:06:50 PM

|

|

Re: Ocean Rodeo Glide-Allula

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

B-Walnut

April 23, 2024, 04:22:52 PM

|

|

Re: Ocean Rodeo Glide-Allula

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

kiteboarder

April 23, 2024, 03:07:49 PM

|

|

Re: Ocean Rodeo Glide-Allula

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

B-Walnut

April 23, 2024, 02:59:32 PM

|

|

Re: Ocean Rodeo Glide-Allula

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

Dwight (DW)

April 23, 2024, 02:41:07 PM

|

|

Re: Erik Antonson interview with Stacy Peralta

[Random]

|

surfinJ

April 23, 2024, 01:34:42 PM

|

|

Fanatic 8.3 Allwave

[Classifieds]

|

firesurf

April 23, 2024, 01:28:40 PM

|

|

Re: Ocean Rodeo Glide-Allula

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

B-Walnut

April 23, 2024, 01:24:35 PM

|

|

Re: At what age did you, or do you plan to retire?

[Random]

|

surfinJ

April 23, 2024, 01:24:13 PM

|

Recent Topics

Recent Topics

|

Sunova Ghost 8'10 SUP

[Classifieds]

|

kliss99

Today at 05:01:39 AM

|

|

Need a new Impact Vest

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

PonoBill

April 23, 2024, 07:55:28 PM

|

|

Ocean Rodeo Glide-Allula

[Wingsurfing, Windfoiling, Wingfoiling, Wing SUP]

|

kiteboarder

April 23, 2024, 06:06:50 PM

|

|

Erik Antonson interview with Stacy Peralta

[Random]

|

surfinJ

April 23, 2024, 01:34:42 PM

|

|

Fanatic 8.3 Allwave

[Classifieds]

|

firesurf

April 23, 2024, 01:28:40 PM

|

|

At what age did you, or do you plan to retire?

[Random]

|

surfinJ

April 23, 2024, 01:24:13 PM

|

|

Jimmy Lewis Super Frank

[Classifieds]

|

firesurf

April 23, 2024, 01:17:06 PM

|

|

WTB: Kalama E3 Wing Board - 131 ltr or 141 ltr

[Classifieds]

|

FedorBOS

April 22, 2024, 08:47:48 AM

|

|

Axis Foil and Parts for Sale

[Classifieds]

|

FedorBOS

April 22, 2024, 08:45:41 AM

|

|

Sunova Faast Pro Allwater 14x27

[Classifieds]

|

gcs

April 21, 2024, 07:15:09 PM

|

|

Starboard Pro vs. Infinity Blurr v2, thoughts?

[SUP General]

|

surfafrica

April 20, 2024, 05:37:26 PM

|

|

Surfboards (Longboards)

[SUP General]

|

Dusk Patrol

April 19, 2024, 12:51:49 PM

|

|

SUP Longboard

[Gear Talk]

|

AndiHL

April 17, 2024, 10:23:58 PM

|

|

Lahonawinds WIND HAWK-Inflatable Wingboard

[Classifieds]

|

kitesurferro

April 16, 2024, 05:12:26 AM

|

|

SIC Raptor Foil and Board For Sale

[Classifieds]

|

addapost

April 15, 2024, 04:25:26 PM

|

|